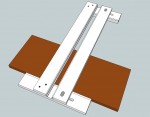

139 – Exact-Width Dado Jig

Video - February 10, 2011

In the Weekend Wall Shelf episode, I showed you how to use a parallel jig to create dados. But the jig was originally created for making coves at the tablesaw. So here’s a special jig made specifically for the purpose of creating dados with your router. The best part is, you can get exact-width dados EVERY TIME!

In the Weekend Wall Shelf episode, I showed you how to use a parallel jig to create dados. But the jig was originally created for making coves at the tablesaw. So here’s a special jig made specifically for the purpose of creating dados with your router. The best part is, you can get exact-width dados EVERY TIME!

This jig was developed and demonstrated in the current Guild Build as part of the Wall-Hanging Cabinet series (it was originally inspired by this Wood Magazine Jig). This video is a little sample of what Guild members are enjoying every week during the build season. If you are interested in joining the Guild, learn more here.

This jig can be made to any size for any bit/guide bushing combination. Just remember that once you use a particular bit/bushing combo with the jig, you are stuck with it. Using a different combination will defeat the purpose of the jig. I used a 5/8″ guide bushing and a 1/2″ router bit.

Don’t forget to download the PDF and SketchUp drawing for the Exact Width Dado Jig!

Jig Modifications

I requested ideas modifications to the jig, and a couple Guild members were quick to off suggestions. If you have a modification, upload it to our SketchUp Library and share the link in the comments below.

Denny’s Suggestion

Robert’s Suggestion (SketchUp File)

Resources

Products Used

- JIG IT(R) Hardware Kit

- sid=AFN86