Dealing With Planer Snipe

Article - February 20, 2007

What is Snipe?

Some planers (sometimes jointers and drum sanders too) have a really annoying habit of digging in deeper at the beginning and/or ends of boards. This phenomenon is called snipe. It can be a very minor dip that only becomes visible when applying finish, or it can be severe as in the photo to the left.

Some planers (sometimes jointers and drum sanders too) have a really annoying habit of digging in deeper at the beginning and/or ends of boards. This phenomenon is called snipe. It can be a very minor dip that only becomes visible when applying finish, or it can be severe as in the photo to the left.

Planers and drum sanders have two pressure rollers, on either side of the cutter/drum head. The rollers hold the board down so that it registers consistently as it passes through the machine. But at the beginning and also at the very end of the pass, the board is only being held down by one roller. Snipe occurs when the board lifts slightly, due to the fact that it is only being held down by this single roller. The end result is a board that is just a hair thinner at the leading and trailing 3-4 inches.

Planers and drum sanders have two pressure rollers, on either side of the cutter/drum head. The rollers hold the board down so that it registers consistently as it passes through the machine. But at the beginning and also at the very end of the pass, the board is only being held down by one roller. Snipe occurs when the board lifts slightly, due to the fact that it is only being held down by this single roller. The end result is a board that is just a hair thinner at the leading and trailing 3-4 inches.

Dealing With Snipe

Since snipe can sometimes be very subtle, its important to look for it during your finish prep. Wetting the surface with mineral spirits can sometimes reveal a trouble area. And one way to really amplify problems on the surface is to use a raking light. Any light shining over the surface at a very low angle will achieve the desired effect. The reason why this works is because the low angle of the light creates a very long shadow for anything sitting proud of the surface. This makes it very easy for our eyes to see. A good analogy is to think of what happens in the city when the sun rises and sets. When the sun is at that low angle, the shadows of the buildings are very long. The longer the shadow, the taller the building. So any surface flaws are amplified by this shadow effect. This is very handy before, during, and after finishing and will improve the overall quality of your finish. Pardon the digression, but I love the raking light!

Now if you know your machines are prone to snipe, you can always leave your boards about 4-6″ long on both sides. That way you can cut each end off before finish sanding. So those are two potential fixes. Lets talk prevention.

Preventing Snipe

One thing you can do is run scrap pieces in front of and behind your good work piece. These sacrificial pieces seem to help even out the pressure from the rollers, resulting in a clean even cut on your project board. And don’t worry too much about the sacrificial pieces. These are going to be very useful later as test pieces for your joinery setups. Its always good to have extra stock around for setups.

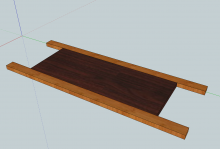

In a similar vein, you can use long support rails to prevent snipe. By attaching a couple of strips of wood, about a foot longer than your workpiece (but equally thick), you’ll wind up with snipe-free boards all day long.

In a similar vein, you can use long support rails to prevent snipe. By attaching a couple of strips of wood, about a foot longer than your workpiece (but equally thick), you’ll wind up with snipe-free boards all day long.

One final method, which is the least amount of work, is to simply lift on the back end of a board and the front is contact the cutter/drum head. This helps to keep the front end of the board down on the table and should significantly decrease the amount of snipe. Of course you’ll need to lift up on the end on the way out as well.